Titanium Hydraulic Manifold Valves: The Future of Efficient Fluid Control

In the ever-evolving realm of industrial technologies, titanium hydraulic manifold valves stand out as a key innovation in fluid control systems. These valves are critical components that manage the flow of fluids in hydraulic systems and are increasingly favored for their durability, lightweight nature, and resistance to corrosion. This article delves into the world of hydraulic manifold valves, focusing specifically on titanium variants, their benefits, applications, and why they are becoming the go-to choice for manufacturers and suppliers alike.

Understanding Hydraulic Manifold Valves

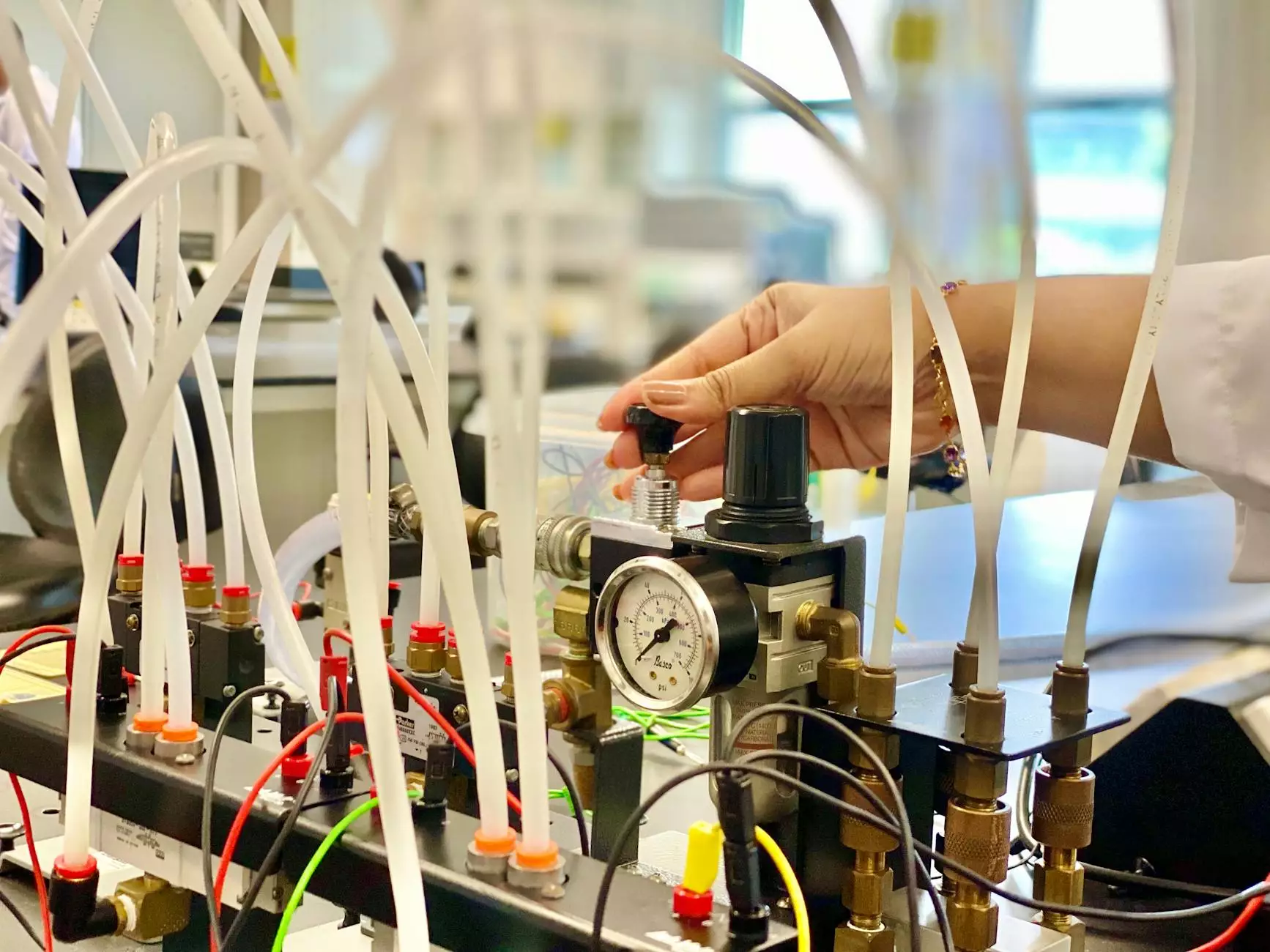

Hydraulic manifolds are integral to hydraulic systems, serving as the central hub where various hydraulic lines converge. The manifold valves control the flow and direction of hydraulic fluid, enabling the transfer of energy necessary for machine operation. These valves can be complex assemblies that incorporate multiple ports and actuators, providing a seamless control interface.

Key Components of Hydraulic Manifold Valves

- Ports: Entry and exit points for hydraulic fluid.

- Actuators: Mechanisms that operate the valve to control flow.

- Body: Typically crafted from durable materials, housing the internal components.

- Seals: Ensuring no leakage occurs at the joints and connections.

Why Choose Titanium for Hydraulic Manifold Valves?

While various materials are employed in the production of hydraulic manifold valves, titanium is gaining a reputation for its advanced performance characteristics. The selection of this alloy offers several advantages that enhance the functionality and longevity of the valves, including:

1. Exceptional Strength-to-Weight Ratio

One of the standout features of titanium is its superior strength-to-weight ratio. In applications where reducing weight is critical, such as in aerospace or automotive industries, titanium hydraulic manifold valves facilitate efficient designs without compromising performance.

2. Outstanding Corrosion Resistance

Titanium exhibits exceptional resistance to corrosion, particularly in challenging environments plagued by saltwater or harsh chemicals. This property ensures that components remain intact and functional over time, thereby reducing maintenance costs and prolonging valve life.

3. High Thermal Stability

High temperatures can severely impact the performance of hydraulic systems. Titanium can withstand extreme temperatures without deforming or losing structural integrity, making it ideal for high-performance applications.

Applications of Titanium Hydraulic Manifold Valves

The versatility of titanium hydraulic manifold valves allows them to be utilized in a range of industries. Their unique properties make them suitable for various applications:

Aerospace and Aviation

In the aerospace sector, where weight reduction is paramount, titanium manifold valves are used in hydraulic systems for aircraft. Their ability to operate efficiently under varying temperatures and pressures makes them a preferred choice.

Marine and Offshore Applications

Marine environments pose significant challenges due to exposure to saltwater. Titanium’s resistance to corrosion makes its manifold valves ideal for offshore oil drilling rigs and marine vessels, ensuring reliable operation in harsh conditions.

Automotive Industry

Many leading automotive manufacturers are adopting titanium components to enhance the performance and efficiency of their hydraulic systems, particularly in performance vehicles.

Industrial Equipment

In general industrial applications, titanium hydraulic manifold valves are crucial for operating machinery that requires reliable and consistent hydraulic performance. They are particularly valuable in sectors such as manufacturing and construction.

Advantages of Partnering with a Reliable Supplier

When it comes to acquiring titanium hydraulic manifold valves, partnering with a reputable supplier like Samvay Global can significantly affect the overall performance of your hydraulic systems. Here are several benefits you can expect when working with industry leaders:

1. Quality Assurance

Established suppliers maintain high standards in manufacturing processes to ensure the production of robust, high-quality valves that meet international specifications. They often provide documentation and warranties that offer peace of mind regarding product performance.

2. Customized Solutions

Reputable manufacturers can create tailor-made solutions that meet specific operational requirements. Whether you need a unique design or specific operating parameters, working with a knowledgeable supplier will help you achieve your goals.

3. Technical Support and Expertise

Top suppliers invest in technical support and are equipped with knowledgeable staff ready to assist with product selection, installation, and maintenance. Access to expert advice can greatly enhance the performance of your systems.

Conclusion: The Bright Future of Titanium Hydraulic Manifold Valves

In conclusion, the evolution of titanium hydraulic manifold valves is a testament to the advancements in material science and engineering. Their distinctive properties offer compelling advantages, making them an essential component across numerous industries. For businesses looking to improve efficiency and reduce maintenance costs, investing in titanium valves is a decision that will pay off in the long run. By working with esteemed manufacturers and suppliers like Samvay Global, you can ensure that your hydraulic systems operate flawlessly, empowering your business toward greater success.

To learn more about our valve supplier, valve manufacturer, fittings supplier, and fittings manufacturer offerings, visit samvayglobal.com today!