The Power of TruPrint in 3D Printing: Revolutionizing Industries

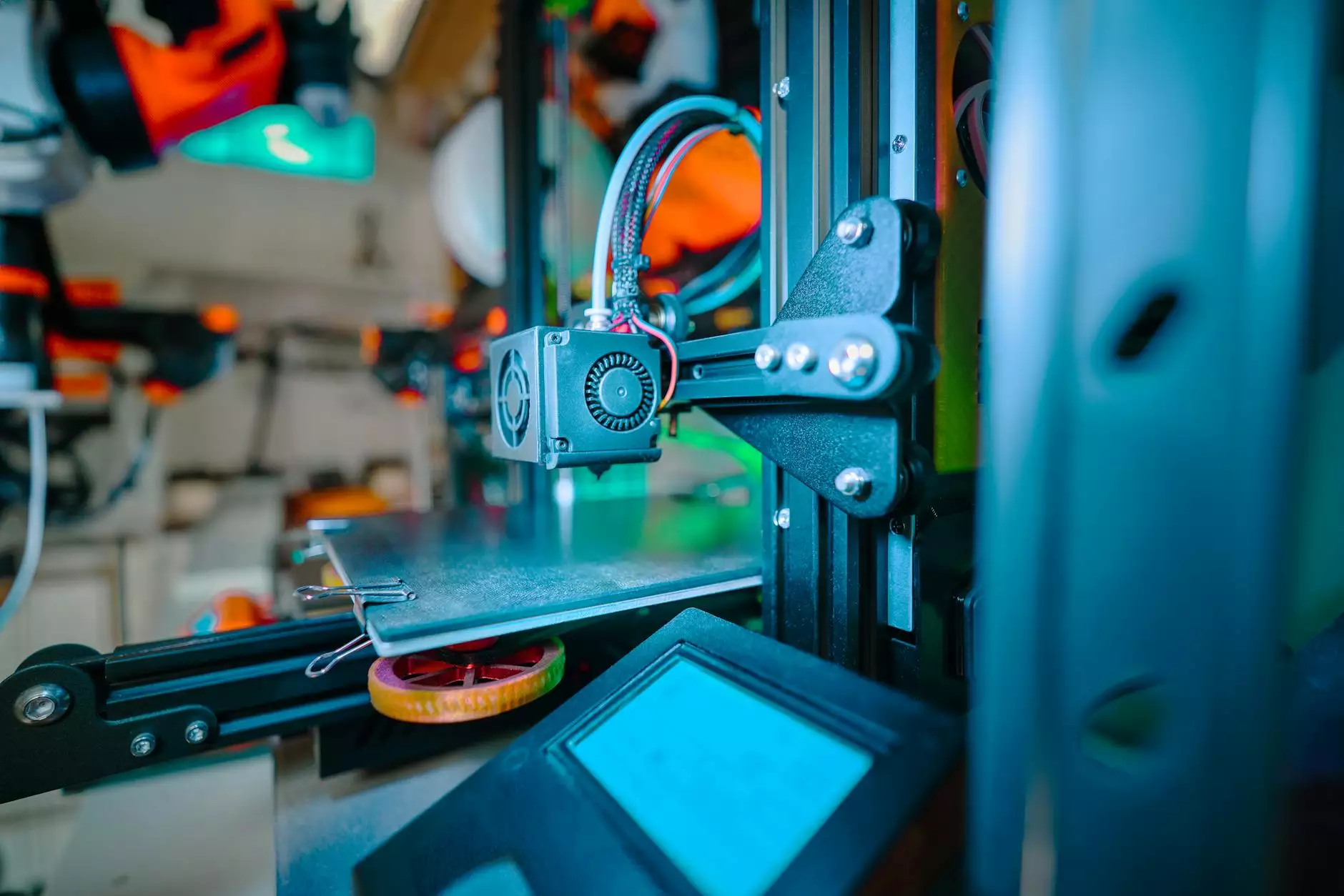

In recent years, the world of manufacturing has witnessed a remarkable transformation brought about by advancements in 3D printing technologies. Among the leaders in this field is TruPrint, a cutting-edge solution that is not only enhancing production efficiency but also reshaping the very foundation of how businesses operate.

Understanding 3D Printing and Its Importance

3D printing, or additive manufacturing, involves creating three-dimensional objects from a digital file by laying down successive thin layers of material. This innovative technology has disrupted traditional manufacturing methods by offering unparalleled flexibility, reducing lead times, and minimizing waste.

Key Advantages of 3D Printing

- Customization: 3D printing allows for the creation of custom products tailored to specific needs.

- Reduced Waste: As materials are added layer by layer, there is less scrap material compared to subtractive processes.

- Speed: Rapid prototyping capabilities speed up the product development cycle.

- Cost-Effectiveness: Lower setup costs for small production runs make 3D printing an attractive option for startups and SMEs.

Introducing TruPrint: A Leader in 3D Printing Technology

TruPrint is more than just a name in the 3D printing industry; it represents a commitment to quality, efficiency, and innovation. Designed to meet the needs of various sectors including aerospace, automotive, and medical, TruPrint machines are equipped with state-of-the-art technologies that significantly enhance production capabilities.

Core Features of TruPrint

What sets TruPrint apart from other 3D printing solutions? Here are some of its standout features:

- Multiple Laser Systems: Utilizing multiple lasers allows for faster build speeds and improved surface quality.

- Large Build Volume: The design accommodates larger parts and complex geometries, expanding possibilities for manufacturers.

- Integrated Systems: The ability to integrate with various software and hardware ecosystems streamlines workflow.

- High Material Compatibility:TruPrint supports a wide range of materials, from metals to polymers, enhancing versatility.

Applications of TruPrint Across Various Industries

The versatility of TruPrint means it has a diverse range of applications across many industries:

Aerospace

In the aerospace industry, weight reduction is critical. TruPrint enables the production of lightweight components that do not compromise on strength or durability. This capability leads to significant fuel savings and increased efficiency in aircraft design.

Automotive

The automotive sector benefits from TruPrint through rapid prototyping and the production of custom parts, enabling manufacturers to innovate quickly and meet consumer demands.

Medical

In medicine, personalized implants and prosthetics created using TruPrint can be tailored specifically to individual patients, dramatically improving surgical outcomes and patient satisfaction.

Benefits of Adopting TruPrint Technologies for Businesses

Investing in TruPrint technology offers numerous advantages for businesses:

Enhanced Productivity

With the efficiency of TruPrint, companies can expect faster turnaround times and increased output, allowing them to respond to market changes more effectively.

Lower Operational Costs

Given the reduced material waste, lower labor costs, and decreased need for tooling, businesses utilizing TruPrint can see a significant reduction in overall operational costs.

Innovation and Market Leadership

Companies that leverage TruPrint's capabilities are better positioned to innovate, giving them a competitive edge in a fast-evolving market landscape.

Case Studies: Success Stories with TruPrint

Real-world applications of TruPrint illustrate its impact on business success:

Case Study 1: Aerospace Manufacturer

An aerospace manufacturer implemented TruPrint systems to produce complex engine components. The switch resulted in:

- 30% reduction in part weight

- 50% decrease in material costs

- Significantly quicker prototype testing phases

Case Study 2: Medical Device Innovator

A medical device company utilized TruPrint to create custom orthopedic implants, achieving:

- Improved patient outcomes

- Reduced manufacturing lead times

- Enhanced product customization options

The Future of 3D Printing with TruPrint

The future of manufacturing is bright, thanks to continuous improvements and innovations in 3D printing technologies like TruPrint. The integration of AI and machine learning with 3D printing processes is anticipated to further enhance production capabilities, leading to smart manufacturing environments.

Emerging Trends

The following trends are shaping the future of TruPrint technology:

- Sustainability: Increasing focus on eco-friendly materials and energy-efficient processes.

- Mass Customization: Ability to produce customized products at scale, catering to individual customer needs.

- Integration with IoT: Smart factories that leverage data analytics and connectivity for better decision-making.

Conclusion: Embracing TruPrint for Business Growth

In conclusion, embracing TruPrint technology is not just about keeping up with trends; it's about positioning your business for future growth. As industries continue to evolve, the ability to adapt and innovate will be key differentiators in achieving long-term success. Companies investing in TruPrint today are paving the way for a more efficient, sustainable, and customer-focused tomorrow.

Explore how TruPrint can transform your business operations and unlock new opportunities. Harness the future of manufacturing with unparalleled precision and capabilities, and be part of an industry revolution that is just beginning to unfold.